truxor T-series

Truxor T30

The Truxor T30 is optimized with the latest environmental requirements and a petrol engine from Kubota. The engine offers high torque at low engine speeds. With low engine speeds, fuel consumption becomes lower.

The T30 Tool Kit

Comes with five hydraulic outlets. The powerful engine makes T30 suitable for work with all tools in our range.

Truxor T30 |

Technical Specifications |

| Item No: |

94-T30 |

| Motor: |

Output - 33 kW/44 hp at 2,600 rpm Torque - Max torque 118.0 Nm at 2400 rpm Cooling System - Combined engine/hydraulic system. The air intake of the radiator is equipped with a filter (prevents dirt in the radiator cells). Thermostat controls the hydraulic oil temperature, improving machine performance Diesel Tank - 35l petrol tank |

| Electric system: |

Battery - 12V/60Amp, 45ah battery Work Lights - 4 LED work lights (2 at front, 2 at back) Stop and Warning Systems - Automatic stop function if the engine overheats or the oil pressure is too low. Warning system for driving at maximum slope |

| Hydraulic system: |

Hydraulic Pump - Maximum system flow 60cm3/r 160l/min Hydraulic Power - 22.2hp Hydraulic Tank - 19l, system 35l, Cyclone technology forced ventilation Spill Safety - Environmentally friendly system with automatic stop of the diesel engine if the oil level drops by more than 8 liters (minimises oil spills) Hydraulic-Operated Valve - 9 functions Control System - CAN bus control of all valves |

| Driver's Seat: |

Seat - Erganomically adjustable driver's seat with thermostatically controlled electric heated seat. Folding cab. Adjustable controls Dashboard - Digital screen for speed, engine temperature, oil pressure, hour meter, fuel gauge, hydraulic oil (temperature, pressure, flow), warnings, engine clock etc Left Joystick - Driving forward/backward/right/left. Speed is controlled by a joystick and with precision driving controls. Control for hydraulic outlet 1 and 2 Right Joystick - Lift, tilt, weight distribution, hydraulic outlet 3 Hydraulic Outlet 1 (front) - Working pressure 140 bar, adjustable flow 0-20l/min Hydraulic Outlet 2 (front) - Working pressure 130 bar, adjustable flow 0-11l/min Hydraulic Outlet 3 (front) - Working pressure 200 bar, adjustable flow 0-60l/min Hydraulic Outlet 3 (rear) - Working pressure 200 bar, adjustable flow 0-60l/min Hydraulic Outlet 4 (rear) - Working pressure 130 bar, adjustable flow 0-11l/min |

| Dimensions |

Total Length - Max. 5030mm, Min. 4700mm Total Width - 2080mm Total Height - Max. 2600mm, Min. 2020mm Weight - 1380kg |

| Miscellaneous |

Driving Speed - 0-100m/min Front Lift - Lifting power 250kg, X4 bracket for fast change of tools. Automatic locking of tools Material - Caterpillar track: rubber with strong plastic paddles and slide rails. Pontoons: Saltwater resistant aluminium. Structure: Hot-dip galvanised steel structure Hydraulic Oil Options - Standard Hydraulic Oil or Environmentally Friendly Panolin |

| Guarentee: |

24 months or 1000 hours of operation |

Truxor T20

The T20 Tool Kit

The T20 comes with a single hydraulic outlet (outlet 1) for tool operation, making it suitable for simple tasks such as reed cutting and collecting. The T20 can be fitted with most cutters, grips and grabs as well as the digging arm. Tools that require more power however, such as the dredge pump, cannot be used

Truxor T20 |

Technical Specifications |

| Item No: |

94-T20 |

| Motor: |

Output - 3 Cylinders, hk-kW 18.5-24.8 at 2600rpm Torque - Max torge 80.0Nm at 1700rpm Cooling System - Combined diesel engine/hydraulic system. The air intake of the radiator is equipped with a filter (prevents dirt in the radiator cells). Thermostat controls the hydraulic oil temperature, improving machine performance Diesel Tank - 35l diesel tank |

| Electric system: |

Battery - 12V/40Amp, 45ah battery Work Lights - 4 LED work lights (2 at front, 2 at back) Stop and Warning Systems - Automatic stop function if the engine overheats or the oil pressure is too low. Warning system for driving at maximum slope |

| Hydraulic system: |

Hydraulic Pump - Maximum system flow 45cm3/r 120l/min Hydraulic Power - 14.1hp Hydraulic Tank - 19l, system 33l, Cyclone technology forced ventilation Spill Safety - Environmentally friendly system with automatic stop of the diesel engine if the oil level drops by more than 8 liters (minimises oil spills) Hydraulic-Operated Valve - 6 functions Control System - CAN bus control of all valves |

| Driver's Seat: |

Seat - Erganomically adjustable driver's seat with thermostatically controlled electric heated seat. Folding cab. Adjustable controls Dashboard - Digital screen for speed, engine temperature, oil pressure, hour meter, fuel gauge, hydraulic oil (temperature, pressure, flow), warnings, engine clock etc Left Joystick - Driving forward/backward/right/left. Speed is controlled by a joystick and with precision driving controls. Control for hydraulic outlet 1 Right Joystick - Lift, tilt, weight distribution Hydraulic Outlet 1 (front) - Working pressure 140 bar, adjustable flow 0-20l/min |

| Dimensions |

Total Length - Max. 5030mm, Min. 4700mm Total Width - 2080mm Total Height - Max. 2600mm, Min. 2020mm Weight - 1350kg |

| Miscellaneous |

Driving Speed - 0-100m/min Front Lift - Lifting power 250kg, X4 bracket for fast change of tools. Automatic locking of tools Material - Caterpillar track: rubber with strong plastic paddles and slide rails. Pontoons: Saltwater resistant aluminium. Structure: Hot-dip galvanised steel structure Hydraulic Oil Options - Standard Hydraulic Oil or Environmentally Friendly Panolin |

| Guarantee: |

24 months or 1000 hours of operation |

The T-series – A new generation of Truxor machines

The T-series uses the knowledge gained from it’s predecessors (DM 5045, 5000 etc) to bring many new features. These updates have been rolled out across all machines in the T-series and include:

-

Lightweight chassis in high-strength steel

An erganomic operator's environment with a digital screen

Lifting arm with parallel drive

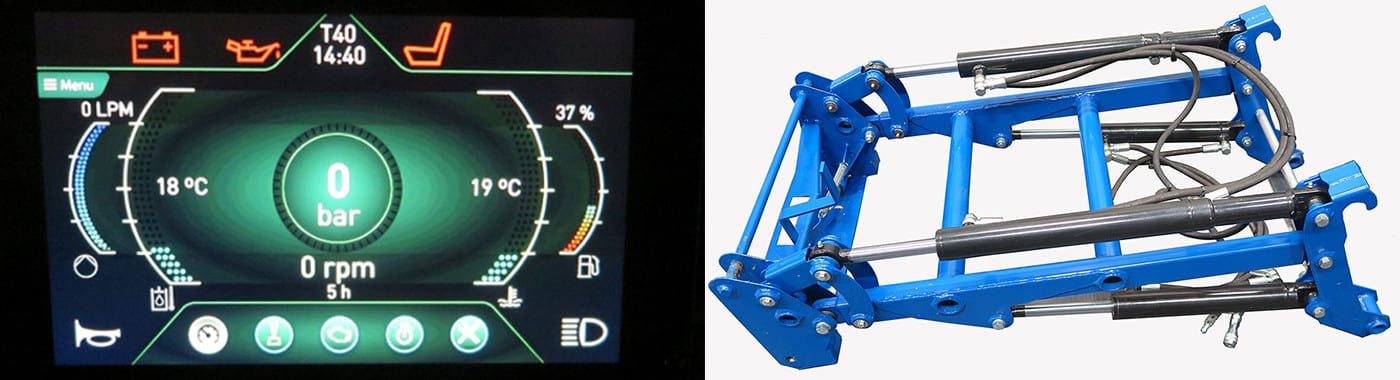

Quick coupler X4 for fast tool replacement

Lockable, retractable storage

LED work lights

Digital technology that improves machine performance and facilitates servicing

...and many more

Digital Screen

The screen provides information from the engine and other systems while providing troubleshooting facilities for service and maintenance. The screen also makes it possible to adjust some of the machine’s functions, such as drive belt balance and speed, flow adjustment of hydraulic outlets, emergency operations etc.

Hydraulic System with Thermostat

The performance of a hydraulic system increases when the hydraulic oil temperature exceeds 40 degrees. A thermostat constantly controls the minimum temperature, improving performance of the machine.